what is the difference between rockwell and vickers hardness test|vickers hardness conversion chart : purchasing Quicker and cheaper than the Brinell and Vickers tests, the Rockwell test requires no material prep, and hardness value is easily readable without any extra equipment, making this one of . webTikToker | Singer | +18 💌

[email protected]

{plog:ftitle_list}

webSe trabalha na zona das Amoreiras, pode escolher entre duas opções práticas: a oficina localizada no posto da Galp na Av. Eng. Duarte Pacheco, a 400 metros das torres das .

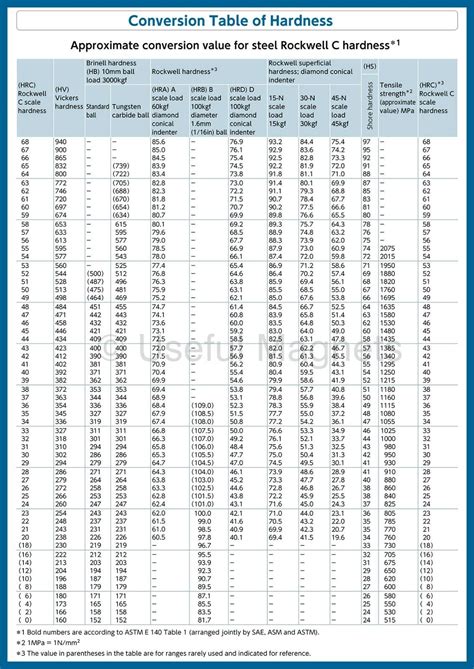

vickers hardness to rockwell conversion

There are three principal standard test methods for expressing the relationship between hardness and the size of the impression, these being Brinell, . Quicker and cheaper than the Brinell and Vickers tests, the Rockwell test requires no material prep, and hardness value is easily . The three most well known and widely used hardness tests for metals today are Brinell, Rockwell, and Vickers. Here are the basic differences explained. 713-827-0700

Rockwell Hardness Test: Hardness is calculated by applying a load to the surface of the test material and measuring the depth of the residual impression after the load is released. Vickers Hardness Test: A diamond-shaped diamond .

Quicker and cheaper than the Brinell and Vickers tests, the Rockwell test requires no material prep, and hardness value is easily readable without any extra equipment, making this one of .

This chapter will explore the key differences between Rockwell and Vickers hardness tests to help you understand their unique characteristics and applications. 1. Testing Principle. The Rockwell hardness test measures .The advantage of Brinell over Rockwell is that the whole range is covered on the scale, whereas in the Rockwell C scale when the hardness is below 180 HB, you must switch to Rockwell B. Vickers is a common unit for measuring the .This chapter will explore the key differences between Rockwell and Vickers hardness tests to help you understand their unique characteristics and applications. 1. Testing Principle. The Rockwell hardness test measures .

Vickers hardness test; The Vickers hardness test can be a macro or micro hardness test as it can bear a load up to 50 kg. The process of the Vicker hardness test is the same as the Knoop test but the indenter used hare is a .

Differences between Rockwell and Vickers hardness test. Let’s have a look at the key differences between Rockwell and Vickers hardness tests that you must know: What is the Rockwell hardness test? The Rockwell hardness . The Knoop hardness test is an alternative to the Vickers hardness test in the micro hardness testing range, and it can be performed on the same universal or micro hardness testing machine. It is mainly used to overcome cracking in brittle materials, as well as to facilitate the hardness testing of thin layers.

Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. . It’s also critical to specify the correct load for Knoop tests because too-light loads could produce falsely high hardness readings. For Vickers tests, too-light loads create too-small indentations on a part, which leads to .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.The Vickers method has higher accuracy than the Brinell method and can be used to measure softer materials, making it suitable for most applications. Do you know the differences between the Vickers and Brinell method? Here's the comparison: Vickers vs Brinell.The Rockwell hardness test method has a whopping 30 hardness scales defined by the indenter and the two loads. A Rockwell hardness value is a combination of the numerical hardness number and the Rockwell hardness scale letters preceded by letters HR. For example, a hardness value of 70 on Rockwell scale A is written 70 HRA.

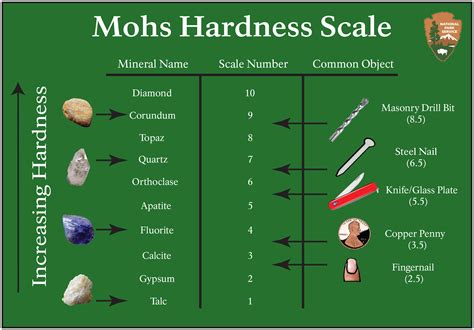

Rockwell, based on difference in indentation depth from the imposition of minor and major loads and Brinell, determined from indention size. Name and briefly describe the two different micro indentation hardness testing techniques, and cite situations for .Study with Quizlet and memorize flashcards containing terms like 1. Which hardness testing method measures in units DPH?, 2. In which hardness testing method does an experienced operator test the material by scratching the surface?, 3. Which hardness testing method uses a 15N Scale? and more.

vickers hardness to mohs scale

Hardness testing is one of the most widely used material testing methods. Static hardness measurements are convenient for accurately determining the hardness. . Unlike Brinell’s and Vickers’s methods, Rockwell’s method does not measured the size of the imprint, but the depth of penetration of the indenter. . Angelovska, Emilija . 1. Rockwell hardness is easy to operate, can read directly, and has a small indentation. It is suitable for batch and finished product production, but it requires multi-point testing to ensure accuracy. Vickers hardness test has a wide range of measurements, covering almost all kinds of materials from soft materials to superhard materials. 2.A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .What is the difference between a Rockwell hardness test and a Vickers hardness test? The main difference between the two methods is the type of indenter and indentation created. The Rockwell method uses a hardmetal ball or diamond pyramid indenter, while the Vickers method uses a diamond pyramid.

Conclusion. Brinell and Rockwell hardness tests are valuable methods for evaluating material hardness, each with its own advantages and considerations.While the Rockwell test offers simplicity and faster results, the .

Metal hardness tests are crucial to engineers, metallurgists, and manufacturers in many industries, from automotive, to oil and gas, and aerospace to name a few. Performing a hardness test is a critical step in qualifying metal . The Difference between Rockwell Hardness and Vickers Hardness Rockwell hardness, easy to operate, can be read directly, and the indentation is small, suitable for batch and finished product production, but .Hardness tests of metals are essential to manufacture reliable big machines and automobiles. The hardness test should be first selected according to the needs of the material. You can find answers to questions about the Brinell and Rockwell in the article, as we have clarified the difference between the two tests. Rockwell Hardness Testing. First developed over one hundred years ago, the Rockwell hardness test is a rapid hardness testing method primarily used for quality assurance and production control. . Vickers Hardness Testing. Finally, Vickers hardness testing is most like Knoop microhardness in that it involves loads of no greater than 1kgf and .

Differences Between Vickers and Knoop Hardness TestsThe Vickers and Knoop hardness tests are both methods used to measure the hardness of materials, but they have distinct differences in their application, indentation geometry, and suitability for different materials. Below are the key differences between these two tesDue to this shallow indentation depth, the Knoop method is particularly suitable for testing very thin layers (e.g. aluminium foil). Due the long and narrow (elongated) test indent, the Knoop method is best suited for use with small, longish test specimens, whilst the Vickers method is better for small, rounded specimens (square indentation).

The indent made is measured using a microscope and converted to a hardness scale. The Vickers hardness test is used on materials that are well polished to make it easier for measurements to be taken. Related Article: Hardness Test Comparison: Vickers vs Rockwell. Related Article: What is the Difference between Rockwell, Brinell, and Vickers?Differences between Rockwell and Vickers hardness test. Let’s have a look at the key differences between Rockwell and Vickers hardness tests that you must know: What is the Rockwell hardness test? The Rockwell hardness test is a more commonly used hardness test, which is popular due to its simplicity and versatility. Type of Hardness Tester in Industries Basically, there are few types of hardness testing. But, there are three most common hardness testing used in worldwide which are Vickers, Brinell, and Rockwell. What is the difference between Vickers, Brinell and Rockwell? How do we select the hardness testing machine that should be used?

The Vickers hardness test measures materials with small parts or thin sections. In contrast, the Brinell hardness is used to measure materials with a rough surface, and other methods are unsuitable. The Vickers to Brinell conversion chart can help you convert values between the Vickers and Brinell hardness scales.

Vickers Hardness Testing. Microhardness testing of metals, ceramics, and composites is useful for a variety of applications for which 'macro' hardness measurements are unsuitable: testing very thin materials like foils, measuring individual microstructures within a larger matrix, or measuring the hardness gradients of a part along the cross section.

In general, if you plot the indentation (i.e. Vickers) hardness against the elastic modulus for a large range of materials (using software like CES from Granta makes this really easy since both properties are listed in the database) you will find that the two do increase together. In non-metals, a large fraction of the indentation deformation .

WEBA argiloterapia é uma aliada para combater esses e outros problemas e consiste em uma terapia capilar que envolve a aplicação da argila diretamente no couro cabeludo. Esse é um ponto importante: a argila não deve ser aplicada nos fios, apenas no couro. Isso porque o ingrediente irá secar pouco a pouco em contato com a pele e, se aplicada .

what is the difference between rockwell and vickers hardness test|vickers hardness conversion chart